- Products Line

- Tel. 02-9627105-7

- E-mail. sales@datadesign.co.th

MENU |

|

ONYX

ONYX is a black filament, a micro carbon reinforced nylon made by mixing short fiber carbon fiber with nylon material. It has twice the strength of plastic (1.4 times that of ABS) and high heat resistance, and it is possible to model parts that have no problem as industrial products. The parts modeled using ONYX have an excellent surface finish. |

FIBERGLASS

Fiberglass is the most cost effective fiber material. It is 2.5 times stronger and 8 times harder than the ONYX-only model. Ideal for manufacturing various parts that require strength and toughness. |

|

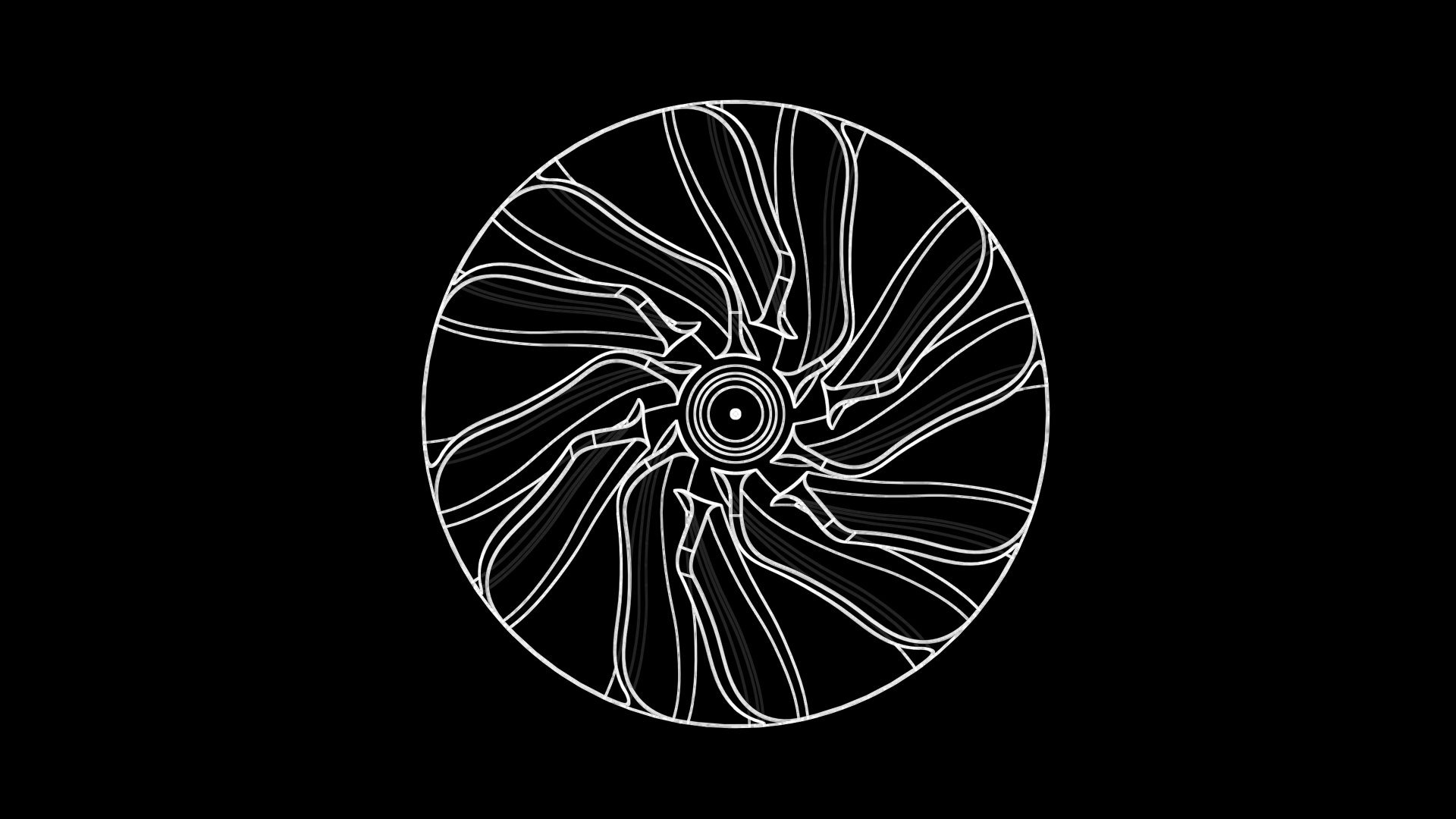

Design

Create part data and upload it in STL format. Select composite materials such as carbon fiber, fiberglass and Kevlar in the software "Eager". |

|

Reinforce

CFF prints one layer at a time. The first nozzle makes a plastic matrix and the second nozzle wraps the fiber all over. |

|

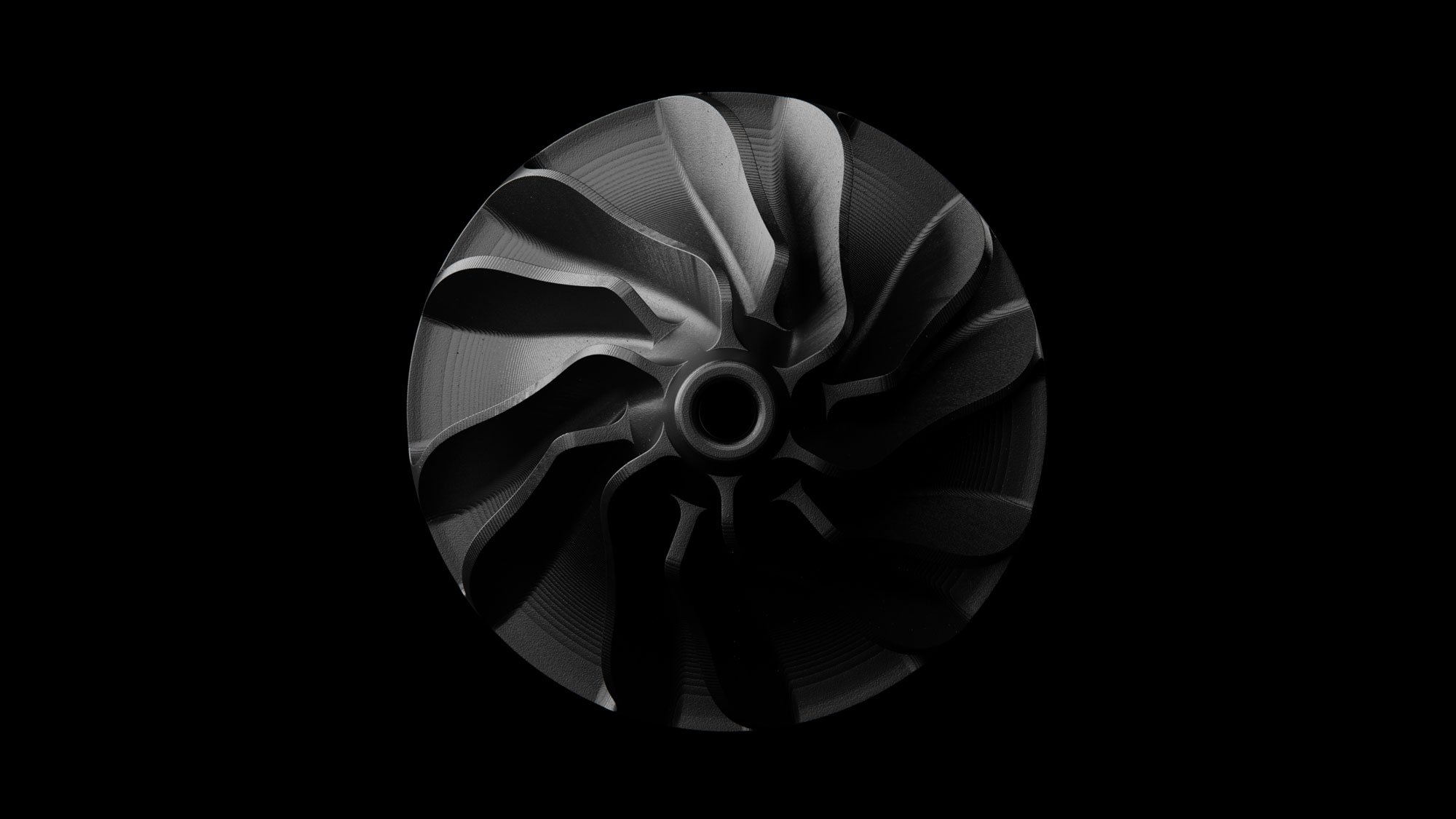

Complete

Formed with CFF technology, which is as strong and lightweight as aircraft grade aluminum, it is ready to use as machining tools, jigs, and prototypes. |

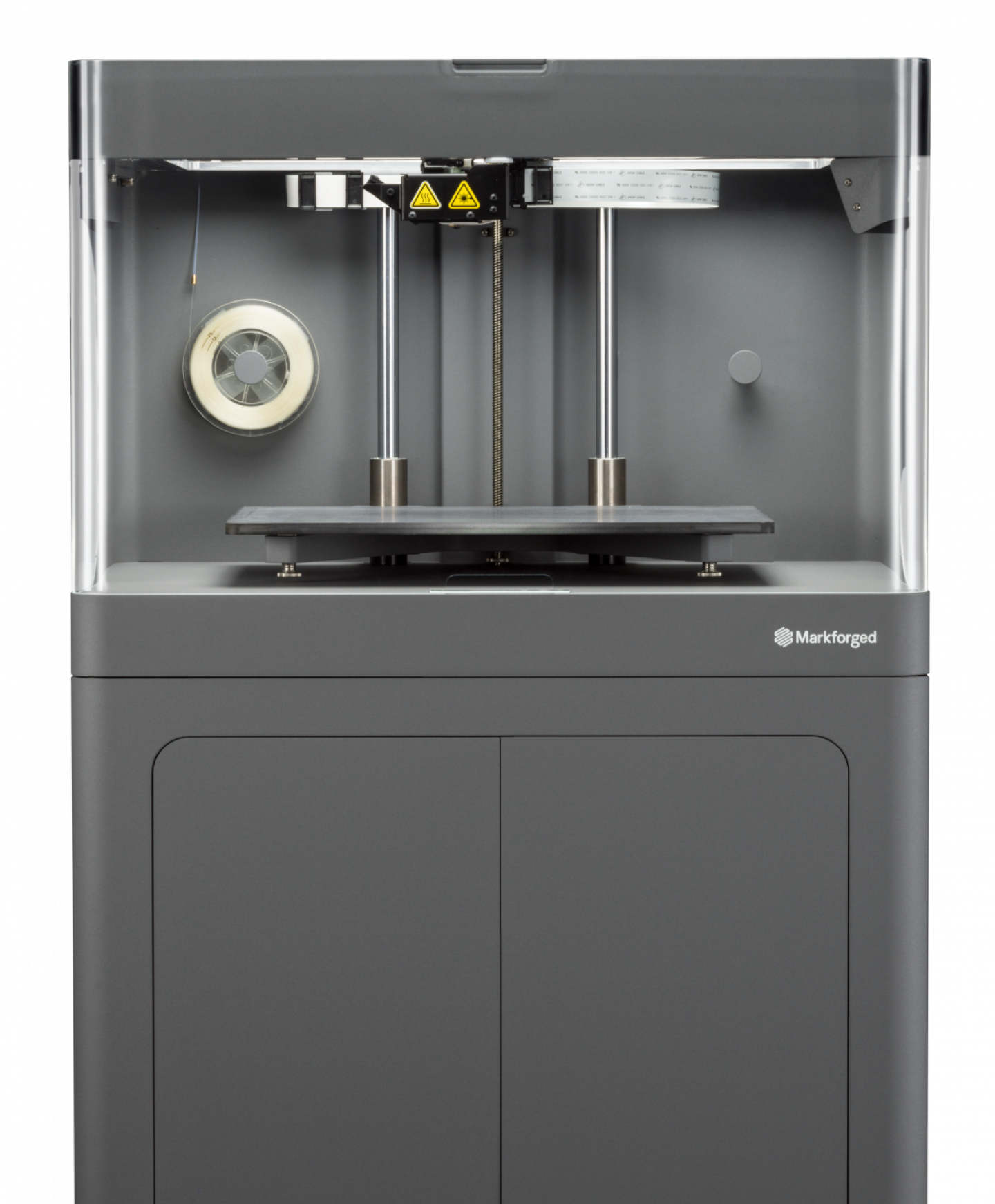

X3 |

X5 |

X7 |

|

Build Volume |

330 mm x 270 mm x 200 mm |

330 mm x 270 mm x 200 mm |

330 mm x 270 mm x 200 mm |

Plastics Material |

Onyx, Onyx FR |

Onyx, Onyx FR |

Onyx, Onyx FR, Nylon white |

Fibers Material |

- |

Fiberglass |

Carbon Fiber, Fiberglass, HSHT Fiberglass, Kevlar |

Z Layer Resolution |

50μm |

50μm |

50μm |

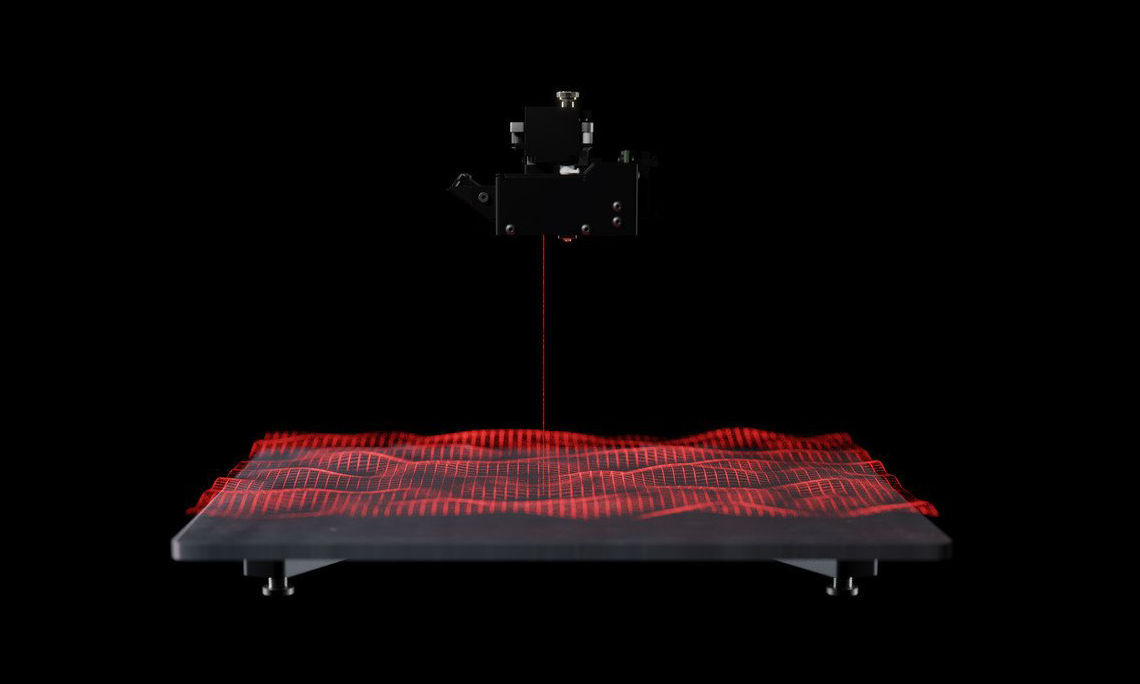

Laser modeling table leveling adjustment |

○ |

○ |

○ |

Laser measurement accuracy |

±1μm |

±1μm |

±1μm |

Laser type in-process inspection |

- |

- |

○ |

Included with printer |

X3 Printer Material cabinet Cloud Eiger Software 800cc Onyx spool |

X5 Printer Material cabinet Cloud Eiger Software 800cc Onyx spool 50cc Fiberglass |

X7 Printer Material cabinet Cloud Eiger Software 800cc Onyx spool 100cc Carbon Fiber 50cc Fiberglass 50cc Kevlar 50cc HSHT Fiberglass |